Standard Ring Frame Tubes

100% IN-HOUSE MOULD MANUFACTURING

- Ring Frame Tube Designing & Mold manufacturing is a highly technical and precision job. And we at KAIPAA have the best equipments & technologies to make so.

- KAIPAA Standard Tubes having different wall thickness like 2.1mm, 2.6mm, 3mm & 4mm are made from different Polymers depending upon the END USER’S Generally Polymers used are Polycarbonate, PC +GF Alloys, PB T Alloys, PBT+PET+GF, Polyamide Alloys.

- Surface Texture of KAIPAA’S Tubes is Unique in itself. It has a combination of Straight grooves, Micro Grooves, Knurling Grooves, Spiral Grooves or a combination of different grooves that is very precisely engineered to uphold yarn firmly during winding and avoids slough offs during unwinding

- Less End Breakages and low TPI variation are the Uniqueness of KAIPAA Ring Tubes

- KAIPAA gives a selection for type of Bush to be inserted in the Tube that depends upon the END User’s application & their manpower working conditions inside the Units.

- Tubes have a special feature of accommodating left out yarn, which is on the spindle. Due to this feature there is no jamming of Tubes on spindle which helps in reducing ideal time of machine and increases life of the Tube.

- Molds of Ring Tubes are manufactured In-house using CNC Machines for achieving very high accuracy.

- Ring Tubes are manufactured on latest technology of Injection Molding Machines, which are fully automatic. Ring Tubes manufactured on these machines are rest assured for best quality & dimensional stability above the international standards

- Due to above technology of Molds and Injection Molding machines the Tubes have very true running for longer period hence less energy consumption.

- KAIPAA Ring Tubes for Manual / Auto Doffing suitable for vide range of machine make like:

- Lakshmi Machine Works

- Toyoda

- Rieter

- Zinser

- Marzoli

- Chinese

- Customized as per the spindle.

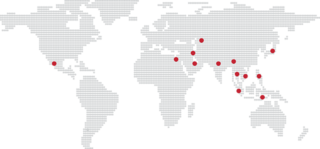

Head Office

Manufacturing Plant

locations

We Are Everywhere